Nick Baines • Model Engineering

Reverser

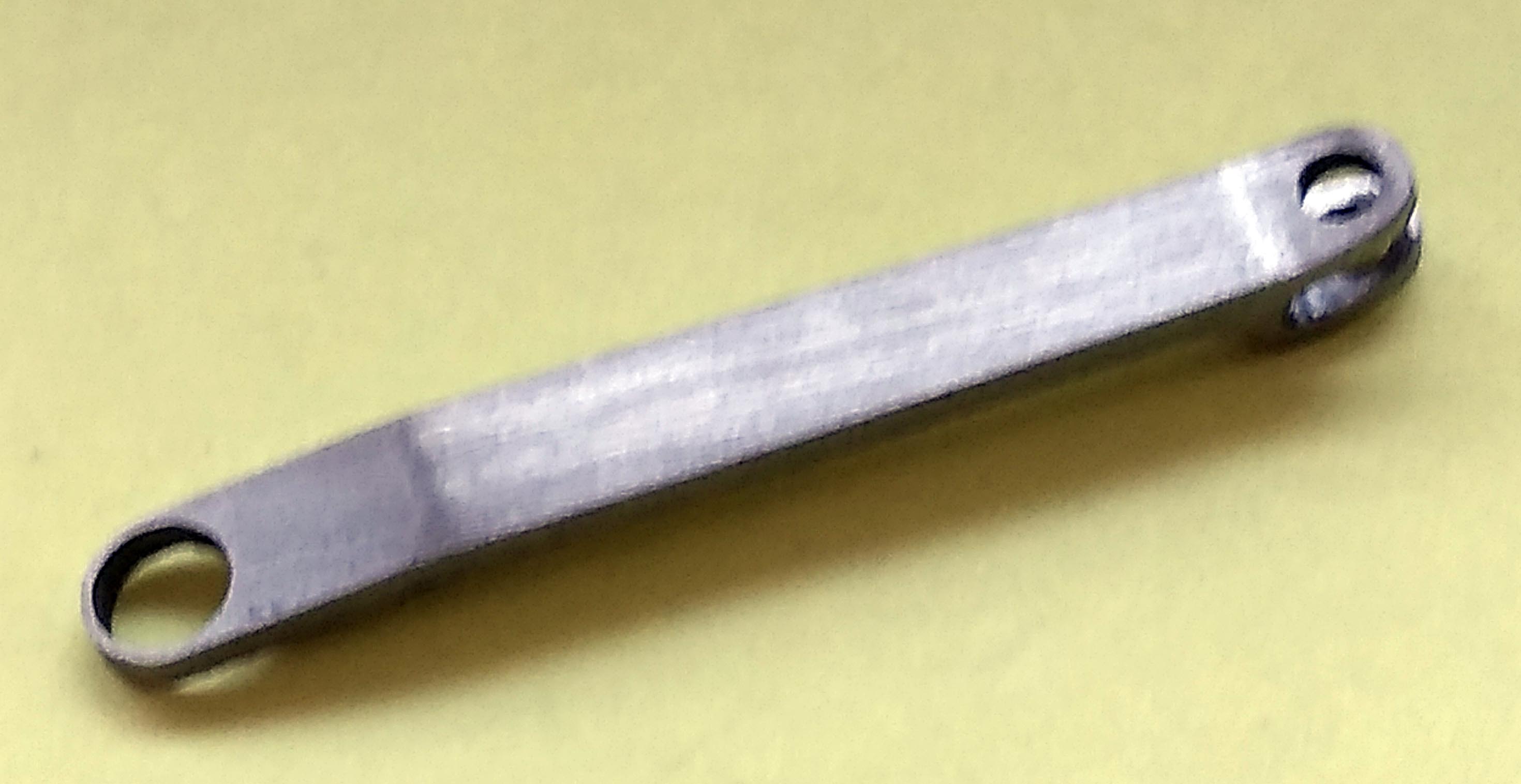

The reversing gear assembly was mostly quite straight forward. The lever was the only tricky part because it is cranked and has a fork end.

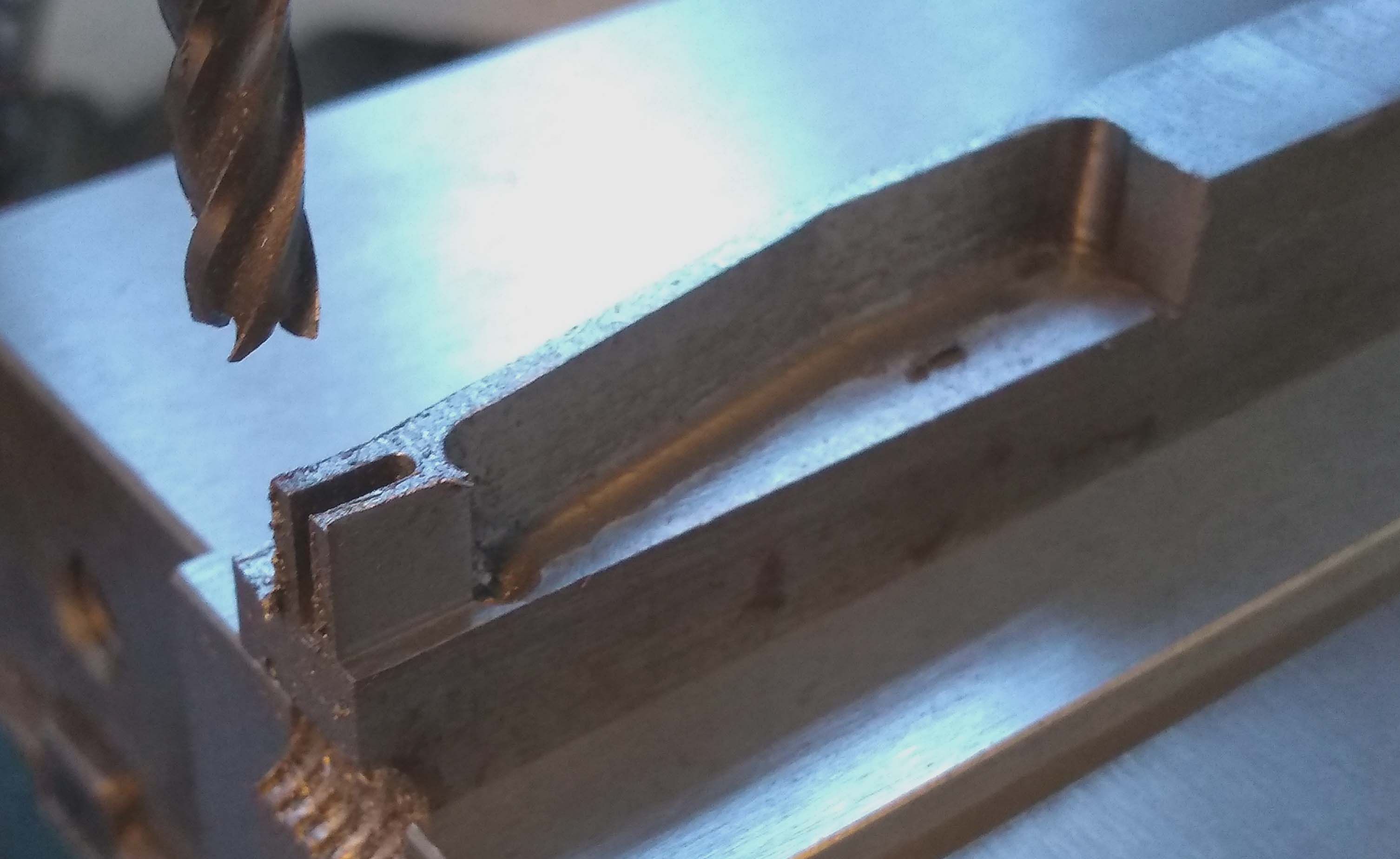

Here it is started on the mill. The fork is cut with a 1.5mm endmill. The photo also shows two holes to start the profile of the lever.

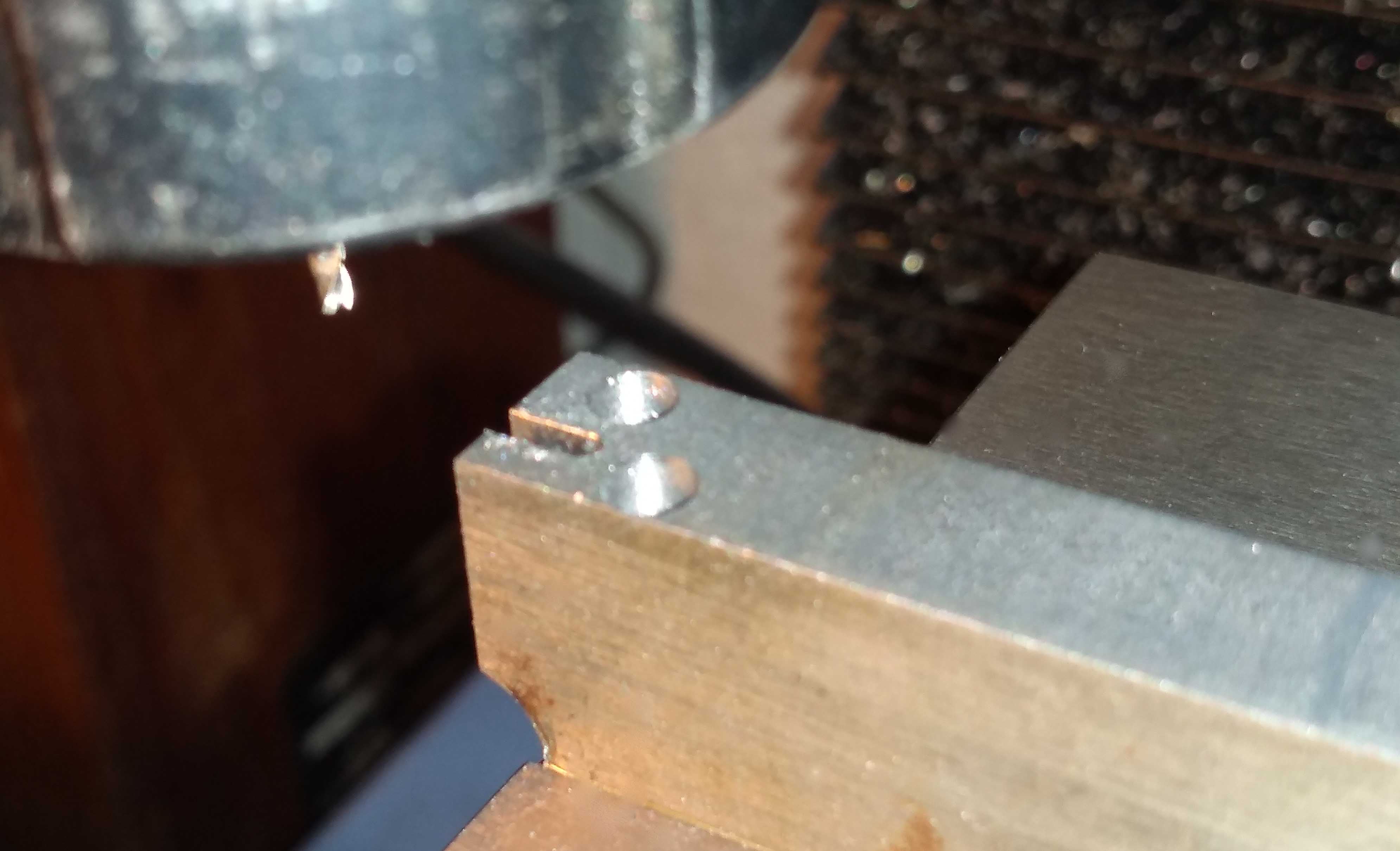

The vice was then set over at an angle in order to cut the crank sides.

It was then cut off using a slitting saw, holes were drilled at each end and the ends were formed on the rotary table. The profile was then finished off using a file.