Smokebox

The smokebox was a lot easier than some that I've done. The main difficulty was getting the rivets round the edges - particularly the front plate. The structure is two plates in fairly heavy gauge material spaced apart.

Nick Baines • Model Engineering

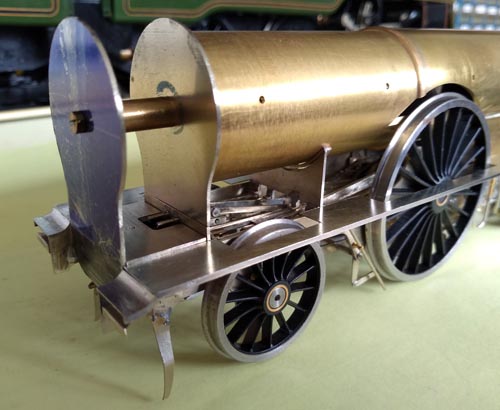

The wrapper was cut to width and approximately to length. The length was to be adjusted when it was bent and fitted into place. Rivets were impressed using the rivetting tool. For anything critical like this I always to a test piece first to check the rivet size and spacing.

The wrapper was then rolled to diameter. Look closely and you can see a piece of card used to prevent the rivets being squashed by the rollers. I also don't use more roller pressure than necessary.

Once that is done the wrapper can be cut to length. There are several rows of rivets to add at each end where, on the prototype, the firebox is secured to the frames.

That took care of the main curve. The reverse curves were done by hand with the aid of a couple of pieces of scrap bar of the right diameter.

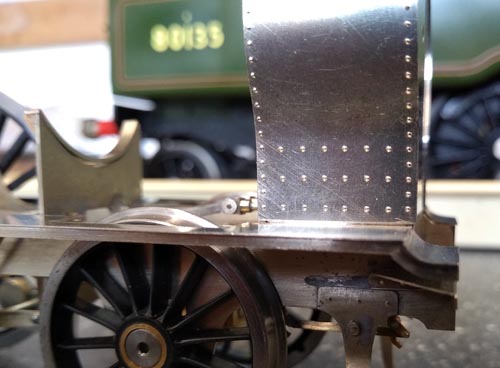

Now for the front. Yes, the structural front was just that, structural, and too heavy to rivet. There is an overlay that carries the rivets. The wrapper extends slightly beyond the structural front to allow for the thickness of the overlay.

Here is the overlay cut to size, rivetted, and soldered in place very carefully to avoid getting solder all over the rivets. No, I didn't avoid that completely and had to do some work with scrapers and fibreglass brushes to clean up. The cylinder covers are Laurie Griffin castings, and the very distinctive triangular valve cover is a scratch component with simulated bolt heads.

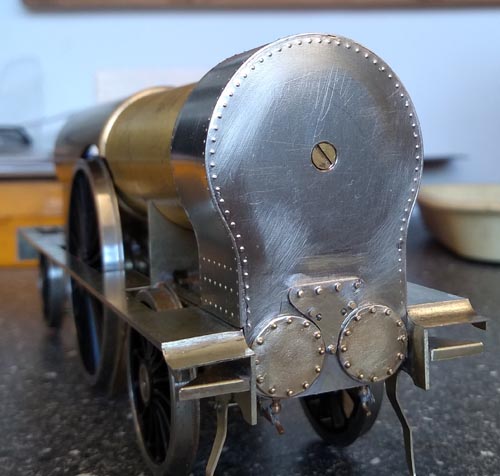

The smokebox door is a turning. It began as a disk of brass which was soldered to a holding plate so that to could be mounted in the lathe.

First cuts to final diameter and the thin ring that is the outermost part of the door.

The central part of the door is a circular arc. The radius turning tool is invalable and makes this so easy.

And there they are. Finally, the hinges and straps were added and the door was glued to the smokebox front. I couldn't solder it without everything else coming adrift but the door carries no load so epoxy is fine. I'm not one of those people who make opening doors to show off a fully detailed smokebox interior.