Nick Baines • Model Engineering

Driving axle springs

On the prototype, Adams used both springing and compensation. A bit of an overkill, perhaps, or maybe he did not think much of the standards of tracklaying at the time. I kept the compensation but made the springs rigid because I could not think of a way to make them sufficiently flexible to be useful. The bogie springs were built up from separate leaves (but still rigid), whereas the driving wheel springs were made from solid. I cannot really favour one method over the other.

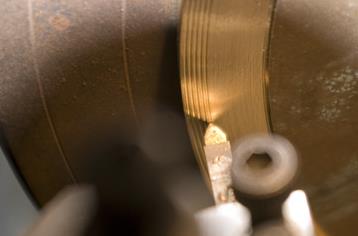

The largest disk of brass that I could find was mounted on the faceplate, and a series of grooves was cut to represent the individual springs. Then the plate was moved to the mill to cut each spring to size. Finally the disk had the four springs required. To part them off, I tried trepanning it (I was not about to bore out so much metal), but even with everything tightened up as far as it could go, I could not stop the chatter. The Myford lathe is just not heavy enough for such treatment. In the end I had to saw the springs off.

And here they are with the eyes and straps silver soldered in place (still some cleaning up required), together with the equalising bars and various bolts and hangers.

Assembling the equalising mechanism.