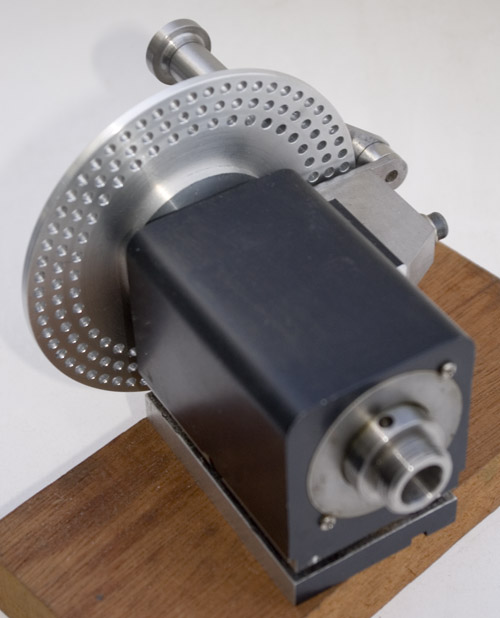

The dividing head is based on a standard Sherline headstock. It may seem somewhat lavish to spend money on a headstock with high-speed precision bearings that are not required, but it was an easy way to the tool I needed, and ensures that it is completely compatible with all the other Sherline accessories.

First it was necessary to modify the headstock so that it could be mounted on the bed of the mill. The photo below shows it set upside down on the mill, and held to an angle plate by the screw holes for the motor bracket. The additional metal on the base that is not required is being machined away. A slot was subsequently cut around the base with a slitting saw so that the dividing head could be secured to the mill table using standard Sherline clamps. Note the sticky tape to keep swarf away from where it should not be.

First it was necessary to modify the headstock so that it could be mounted on the bed of the mill. The photo below shows it set upside down on the mill, and held to an angle plate by the screw holes for the motor bracket. The additional metal on the base that is not required is being machined away. A slot was subsequently cut around the base with a slitting saw so that the dividing head could be secured to the mill table using standard Sherline clamps. Note the sticky tape to keep swarf away from where it should not be.

Dividing head

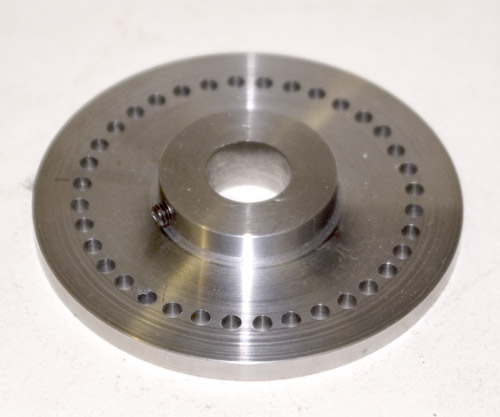

The new components are (a) an index plate, and (b) a spring-loaded plunger on a bracket that locates in the holes in the index plate. The index plate goes where the pulley is usually located, where there is a flat on the shaft to secure it. There is an index plate available from Carter Tools that provides 40, 50, and 60 holes. It needs a hub making to fit it, but that is a fairly simple turning job.

Since I needed other divisions as well, I made another plate with 36 holes by indexing on the Myford lathe using a gear change wheel to get the divisions

There are drawings of the dividing head components and the index plate blank here.

Nick Baines • Model Engineering

The dividing plate from Carter Tools has rows of 40, 50 and 60 holes

Machining the base of the Sherline headstock